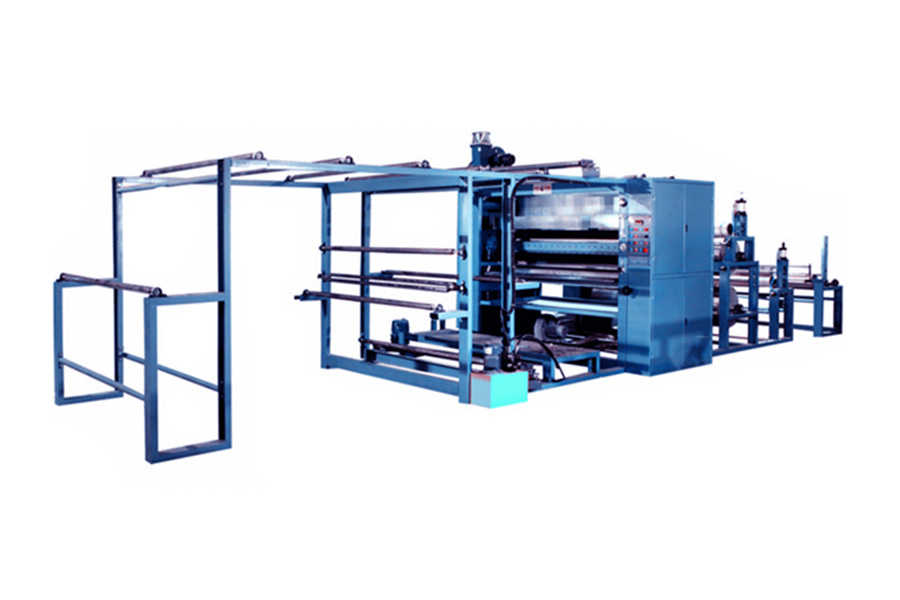

High-Quality Composite Laminating Machine for Efficient Production

By:Admin

In the world of manufacturing, the use of advanced technology and machinery has become increasingly prevalent in recent years. Companies are constantly seeking ways to improve efficiency and productivity, and one of the latest innovations making waves in the industry is the Composite Laminating Machine.

This state-of-the-art machine, which has been developed and manufactured by a leading company in the field of industrial equipment, has the potential to revolutionize the way composite materials are produced. With its advanced technology and precision engineering, the Composite Laminating Machine offers a range of benefits that could have a significant impact on the manufacturing industry as a whole.

One of the key features of the Composite Laminating Machine is its ability to laminate multiple layers of composite materials with unparalleled accuracy and consistency. This is achieved through a combination of advanced robotics, computer-aided design, and high-quality components that work together to ensure that each layer is applied with the utmost precision. As a result, manufacturers can expect a significant reduction in material waste and an increase in the overall quality of their products.

Furthermore, the Composite Laminating Machine is designed to be highly versatile, capable of handling a wide range of composite materials including carbon fiber, fiberglass, and kevlar. This versatility makes it an ideal choice for manufacturers across a variety of industries, from automotive and aerospace to sports equipment and consumer goods. With the ability to work with such a diverse range of materials, the Composite Laminating Machine offers manufacturers the flexibility they need to stay ahead in an ever-changing market.

In addition to its technical capabilities, the Composite Laminating Machine is also designed with the user in mind. Its intuitive interface and user-friendly controls make it easy for operators to set up and run the machine, reducing the need for extensive training and allowing for seamless integration into existing manufacturing processes. This user-centric approach is a testament to the company's commitment to providing practical and efficient solutions for their customers.

Furthermore, the company behind the Composite Laminating Machine is renowned for its dedication to research and development. With a team of highly skilled engineers and technicians, the company continues to push the boundaries of what is possible in the field of composite manufacturing, developing new technologies and refining existing ones to meet the evolving needs of the industry. This commitment to innovation positions the company as a leader in the market, with the Composite Laminating Machine being just one example of their forward-thinking approach.

As the manufacturing industry continues to evolve, the Composite Laminating Machine represents a significant leap forward in the production of composite materials. Its advanced technology, versatility, and user-friendly design make it a valuable asset for manufacturers looking to improve their processes and remain competitive in a demanding market. With the support of the company behind it, the future looks promising for this groundbreaking machine and the impact it will have on the industry as a whole.

Company News & Blog

High-Quality Roll Lamination Machine for SBR Materials

SBR Roll Lamination Machine: Revolutionizing the Lamination ProcessIn today's fast-paced and dynamic business environment, the need for efficient and high-quality lamination solutions has never been greater. With the increasing demand for laminated products across various industries, it is essential for businesses to invest in reliable and innovative lamination equipment that can meet their specific requirements. This is where the SBR Roll Lamination Machine comes into play, offering cutting-edge technology and exceptional performance to streamline the lamination process.The SBR Roll Lamination Machine, manufactured by a leading company in the industry, is a state-of-the-art solution designed to meet the diverse needs of businesses looking to enhance the durability, appearance, and functionality of their printed materials. Whether it's for packaging, signage, or any other application requiring laminated products, this machine has proven to be a game-changer for businesses seeking to elevate their production process.One of the key features that sets the SBR Roll Lamination Machine apart from its competitors is its versatility. With the ability to handle a wide range of substrates, from paper and film to board and foam, this machine offers unmatched flexibility to accommodate various lamination needs. This versatility is further enhanced by its adjustable speed and tension control, allowing users to achieve precise and consistent lamination results with different materials.Moreover, the SBR Roll Lamination Machine is engineered for efficiency and ease of use. Equipped with advanced automation and user-friendly controls, this machine enables operators to maximize productivity while minimizing downtime. Its intuitive design and seamless operation make it an ideal choice for businesses looking to streamline their lamination process without compromising on quality.The durability and reliability of the SBR Roll Lamination Machine are also worth noting. Built with robust components and engineered for long-term performance, this machine is capable of delivering consistent results over an extended period, making it a cost-effective investment for businesses of all sizes.In addition to its impressive technical specifications, the SBR Roll Lamination Machine is backed by a dedicated team of experts who provide comprehensive support and maintenance services. From installation and training to troubleshooting and spare parts supply, the company behind this machine is committed to ensuring that its customers get the most out of their investment.Furthermore, the environmental sustainability of the SBR Roll Lamination Machine is a testament to the manufacturer's commitment to responsible manufacturing practices. By incorporating energy-efficient components and minimizing waste in its production process, this machine aligns with the growing emphasis on eco-friendly solutions in the industry.As businesses continue to adapt to evolving market demands, the SBR Roll Lamination Machine presents itself as a reliable and forward-thinking solution that can propel them towards greater success. With its unmatched performance, versatility, and support services, this machine has already gained traction among businesses seeking to optimize their lamination process.In conclusion, the SBR Roll Lamination Machine has emerged as a frontrunner in the lamination equipment market, offering a winning combination of cutting-edge technology, reliability, and support. As businesses look to stay ahead in an increasingly competitive landscape, this machine has positioned itself as a valuable asset for those seeking to elevate the quality and efficiency of their lamination operations. With its proven track record and customer-centric approach, the SBR Roll Lamination Machine is poised to revolutionize the way businesses approach lamination, setting new standards for excellence in the industry.

New Automatic Thermal Film Laminating Machine Makes Laminating Effortless

With the increasing demand for high-quality packaging and finishing solutions in the printing industry, the introduction of the Automatic Thermal Film Laminating Machine by [Company Name] is poised to revolutionize the way printing companies enhance the visual appeal and durability of their products. This innovative machine offers a seamless and efficient solution for laminating various types of printed materials, making it a game-changer in the industry.[Company Name] has established itself as a leading manufacturer of printing and packaging equipment, with a strong emphasis on research and development to meet the evolving needs of its customers. The company is known for its commitment to innovation, quality, and customer satisfaction, and the introduction of the Automatic Thermal Film Laminating Machine is a testament to this dedication.The Automatic Thermal Film Laminating Machine is designed to streamline the laminating process, offering an automated solution to increase efficiency and reduce production time. This machine is capable of laminating a wide range of materials, including paper, cardboard, and corrugated board, making it a versatile and practical choice for printing companies of all sizes.One of the key features of the Automatic Thermal Film Laminating Machine is its advanced thermal film technology, which ensures a high-quality lamination finish with a smooth and consistent appearance. This technology also enables the machine to operate at an optimal speed, further enhancing productivity and reducing production costs for printing companies.In addition to its advanced technology, the Automatic Thermal Film Laminating Machine is equipped with user-friendly controls and a user interface that allows for easy operation and monitoring of the laminating process. This feature ensures that operators can easily set and adjust the machine to meet specific production requirements, further enhancing its practicality and efficiency.Furthermore, the Automatic Thermal Film Laminating Machine is designed with durability and reliability in mind, with high-quality components and robust construction that can withstand the rigors of continuous production. This ensures that printing companies can rely on the machine to deliver consistent and high-quality laminating results, ultimately contributing to the overall quality of their printed products.The introduction of the Automatic Thermal Film Laminating Machine by [Company Name] is set to have a significant impact on the printing industry, providing printing companies with a reliable and efficient solution to meet their laminating needs. With its advanced technology, user-friendly design, and durable construction, this machine is well-positioned to become a cornerstone of modern printing and packaging operations.As the printing industry continues to evolve and demand higher quality and efficiency, the Automatic Thermal Film Laminating Machine represents a major step forward for [Company Name] in providing innovative solutions that meet the needs of its customers. With this latest addition to its product lineup, [Company Name] is reinforcing its commitment to excellence and innovation, further solidifying its position as a trusted partner for printing companies around the world.In conclusion, the Automatic Thermal Film Laminating Machine by [Company Name] is a groundbreaking addition to the printing and packaging industry, offering a reliable, efficient, and versatile solution for laminating printed materials. With its advanced technology, user-friendly design, and durable construction, this machine is set to make a significant impact on the way printing companies enhance the visual appeal and durability of their products, further reinforcing [Company Name]'s reputation as a leader in the industry.

High-Quality Lamination Machine for Sponge and Textile: Everything You Need to Know

[Company Name] Unveils Cutting-Edge Lamination Machine for Sponge and Textile Production[City, Date] - [Company Name], a leading provider of innovative industrial machinery, has announced the release of their latest cutting-edge lamination machine designed specifically for sponge and textile production. This state-of-the-art machine is set to revolutionize the industry with its advanced technology and unmatched performance.With over [X] years of experience in the industry, [Company Name] has continuously strived to develop innovative solutions to meet the evolving needs of their customers. The new lamination machine is a testament to their commitment to excellence and their dedication to pushing the boundaries of what is possible in the industrial machinery sector.The lamination machine is designed to provide a seamless and efficient lamination process for sponge and textile materials. It is equipped with advanced features that ensure precision, consistency, and reliability, making it the ideal choice for manufacturers looking to streamline their production processes and improve the quality of their products.One of the key features of the lamination machine is its ability to handle a wide range of materials, including sponges and textiles of varying thickness and density. This versatility makes it a valuable asset for manufacturers working with diverse materials and looking to expand their product range.In addition, the machine is designed for easy operation and maintenance, with intuitive controls and a user-friendly interface. This ensures that operators can quickly familiarize themselves with the machine and maximize its potential without the need for extensive training.Furthermore, the lamination machine boasts a high level of energy efficiency, helping to reduce operational costs and minimize environmental impact. This aligns with [Company Name]'s commitment to sustainability and their efforts to develop eco-friendly solutions for the industry."We are very excited to introduce our latest lamination machine for sponge and textile production," said [Spokesperson Name], [Title] at [Company Name]. "This machine represents the culmination of years of research and development, and we are confident that it will set a new standard for efficiency and performance in the industry."The release of the lamination machine comes at a time when the demand for high-quality sponge and textile products is on the rise. Manufacturers are constantly seeking ways to improve the durability and functionality of their products, and the new lamination machine is poised to address these needs with its advanced capabilities.In conclusion, [Company Name]'s latest lamination machine for sponge and textile production is a testament to their ongoing commitment to innovation and excellence in the industrial machinery sector. With its advanced technology, versatility, and energy efficiency, the lamination machine is set to make a significant impact on the industry and provide manufacturers with a competitive edge in the market.For more information about [Company Name] and their range of industrial machinery solutions, visit [website] or contact [contact information].About [Company Name]:[Company Name] is a leading provider of innovative industrial machinery, specializing in the development and production of cutting-edge solutions for various manufacturing processes. With a strong focus on technology, quality, and customer satisfaction, [Company Name] is dedicated to pushing the boundaries of what is possible in the industrial machinery sector.

Water-Based Glue Laminator Machine for Solvent-Free Bonding

Solvent Water-Based Glue Laminator Machine Revolutionizes Lamination ProcessLamination is a commonly used process in the manufacturing industry, where different layers of materials are combined to create a single composite material with improved properties. This process is widely used in various industries such as packaging, printing, and construction. Traditionally, solvent-based adhesives have been used in the lamination process, but with growing concerns about the environmental impact of these adhesives, there has been a shift towards water-based adhesives.In response to this industry trend, {Company Name}, a leading manufacturer of lamination machines, has introduced a revolutionary Solvent Water-Based Glue Laminator Machine that is set to change the way lamination is done. This innovative machine offers a sustainable and environmentally friendly solution for the lamination process, without compromising on performance and quality.The Solvent Water-Based Glue Laminator Machine is designed to effectively apply water-based adhesive to different materials, providing a strong and durable bond without the harmful emissions associated with solvent-based adhesives. This machine is capable of laminating a wide range of materials, including paper, cardboard, and various types of plastic films, making it suitable for a variety of applications.{Company Name} has always been at the forefront of innovation and technology in the lamination industry, and the introduction of the Solvent Water-Based Glue Laminator Machine is yet another example of their commitment to sustainable manufacturing practices. The company prides itself on creating advanced machinery that meets the evolving needs of the industry while prioritizing environmental responsibility.In addition to the environmental benefits of using water-based adhesives, the Solvent Water-Based Glue Laminator Machine offers several other advantages. The machine is easy to operate, with a user-friendly interface and automated features that ensure efficient and consistent lamination results. It also requires minimal maintenance, reducing downtime and increasing productivity for manufacturers.Furthermore, the use of water-based adhesives eliminates the risk of flammability associated with solvent-based adhesives, providing a safer working environment for employees. This is particularly important in industries where lamination is a key part of the manufacturing process.{Company Name}'s Solvent Water-Based Glue Laminator Machine is already receiving positive feedback from early adopters in the industry. Customers have praised the machine for its reliability, performance, and its contribution to their sustainability goals. The switch to water-based adhesives has also resulted in cost savings for many manufacturers, as water-based adhesives are generally more cost-effective than solvent-based adhesives.As the demand for sustainable and environmentally friendly manufacturing processes continues to grow, {Company Name} is well-positioned to meet the needs of the industry with its Solvent Water-Based Glue Laminator Machine. The company's commitment to innovation and sustainability sets it apart as a leader in the field of lamination machinery, and the introduction of this new machine further solidifies its position in the market.In conclusion, {Company Name}'s Solvent Water-Based Glue Laminator Machine represents a significant advancement in the lamination industry, offering a sustainable and efficient solution for manufacturers. With its environmental benefits, ease of use, and excellent performance, this machine is set to redefine the lamination process and pave the way for a more sustainable future in manufacturing.

Top-Rated Laminating Machine Offers Exceptional Quality in China

Title: Advanced Laminating Machines Revolutionizing Manufacturing Efficiency in ChinaSubtitle: An Inside Look at [Company's Name] Industry-Leading Laminating SolutionsIntroduction:China has been at the forefront of manufacturing innovation, constantly striving to improve production efficiency, and deliver superior quality products. Among the many advancements, laminating machines have emerged as key tools revolutionizing production processes. Leading the way in this industry is [Company's Name], a renowned manufacturer that has been delivering cutting-edge laminating solutions to companies across various sectors. With their advanced technology and commitment to excellence, [Company's Name] has become a trusted partner in enhancing productivity and facilitating product development for organizations across China.1. Innovation and Technological Excellence:[Company's Name] boasts a rich history of manufacturing excellence, with a strong focus on research and development. Their laminating machines are the epitome of technical superiority, incorporating state-of-the-art advancements to meet the varied needs of clients. By utilizing the latest technologies, such as high-resolution touchscreens, advanced adhesive application systems, and precision temperature control, [Company's Name] ensures that their laminating machines deliver remarkable efficiency and unmatched quality.2. Versatile Range of Laminating Solutions:Recognizing that different industries have unique requirements, [Company's Name] provides a diverse range of laminating machines tailored to meet specific needs. Whether it's the packaging industry, textile manufacturers, or electronic component production, [Company's Name] offers specialized laminating solutions suitable for each sector. From hot and cold laminating machines to industrial-grade laminators, their comprehensive range caters to organizations of all sizes and complexities.3. Commitment to Environmental Sustainability:[Company's Name] understands the importance of sustainable manufacturing practices. Their laminating machines are designed with eco-friendly features that ensure minimal waste generation and energy consumption. By integrating energy-efficient components and developing recycling systems, [Company's Name] promotes a cleaner production environment, aligning with China's vision of a greener future.4. Customer-Centric Approach:One of the distinguishing factors that set [Company's Name] apart from competitors is their customer-centric approach. The company believes in forging lasting partnerships with their clients, understanding their unique requirements, and providing tailored solutions. Through in-depth consultations, on-site demonstrations, and comprehensive after-sales services, [Company's Name] ensures that customers receive unmatched support throughout their laminating machine journey.5. Quality Assurance:[Company's Name] places utmost importance on product quality and durability. With rigorous quality control measures in place, their laminating machines undergo stringent testing protocols before leaving the factory. This commitment to excellence is reflected in the comprehensive warranties and post-purchase technical assistance that [Company's Name] offers to its customers, giving them peace of mind and reinforcing the reliability of their laminating machines.6. International Reach and Recognition:While [Company's Name] primarily operates within China, its stellar reputation and product excellence have gained international recognition. Partnering with companies worldwide, [Company's Name] has established a global presence, exporting their laminating machines to countries across the globe. Clients from Europe, North America, and Asia have acknowledged the superior performance and reliability of [Company's Name] laminating machines, further solidifying their position as an industry leader.Conclusion:As Chinese manufacturing continues to evolve, [Company's Name] remains at the forefront of innovation, helping businesses across various sectors enhance productivity and product quality through cutting-edge laminating solutions. With their commitment to technological excellence, environmental sustainability, and customer satisfaction, [Company's Name] has earned its place as a trusted partner in China's ongoing industrial revolution.

High-Quality Latex Laminating Machine: A Must-Have for Your Business

The Latex Laminating Machine, the latest innovation from a leading industrial machinery company, is set to revolutionize the manufacturing and production processes in various industries. This cutting-edge machine offers a wide range of benefits and features that are designed to enhance efficiency, productivity, and quality in the production of laminated products.The Latex Laminating Machine is the result of extensive research and development by the company, which has been a pioneer in the industrial machinery and equipment sector for over two decades. Known for its commitment to innovation and quality, the company has established itself as a trusted name in the industry, delivering state-of-the-art solutions to meet the evolving needs of its customers.One of the key features of the Latex Laminating Machine is its advanced technology, which allows for the seamless and precise lamination of various materials. Whether it is fabric, paper, or plastic, this machine can handle a wide range of materials with ease, making it a versatile and valuable asset for manufacturers across different sectors. The machine's ability to deliver consistent and high-quality lamination results is a testament to the company's dedication to excellence and customer satisfaction.Another standout feature of the Latex Laminating Machine is its user-friendly interface and intuitive controls. With a simple and easy-to-navigate design, operators can quickly familiarize themselves with the machine and maximize its potential within their production processes. This not only streamlines operations but also minimizes the need for extensive training, allowing businesses to make the most of their investment from day one.In addition to its technological prowess, the Latex Laminating Machine is also designed with efficiency in mind. Its high-speed operation and automated functions enable swift and smooth lamination processes, which in turn, can help increase overall productivity and output for businesses. This is especially crucial in today's fast-paced manufacturing environment, where time is of the essence, and meeting production deadlines is paramount.Moreover, the Latex Laminating Machine is built to last, with a sturdy and robust construction that ensures durability and longevity. This means that businesses can rely on this machine to deliver consistent performance over an extended period, resulting in cost savings and minimal downtime for maintenance or repairs.Furthermore, the company's dedication to customer support and service further sets it apart from its competitors. With a team of knowledgeable and experienced professionals, the company provides comprehensive assistance, including installation, training, and ongoing maintenance, to ensure that customers can fully optimize the capabilities of the Latex Laminating Machine.Overall, the Latex Laminating Machine represents a significant leap forward in the world of industrial lamination, offering a combination of cutting-edge technology, user-friendly design, efficiency, and reliability. As the manufacturing landscape continues to evolve, this innovative machine stands ready to meet the challenges of tomorrow, empowering businesses to elevate their production processes and deliver superior, high-quality laminated products.In conclusion, the Latex Laminating Machine from the company is a game-changer for industries seeking to enhance their lamination processes. With its advanced technology, user-friendly interface, efficiency, and durability, this machine is poised to set new standards in industrial lamination and contribute to the success of businesses across various sectors. With a track record of excellence and a commitment to customer satisfaction, the company has once again demonstrated its ability to deliver innovative solutions that address the evolving needs of the industry. As businesses continue to pursue excellence in their manufacturing processes, the Latex Laminating Machine stands as a testament to the company's vision and dedication to driving progress and innovation.

Laminating Machine for White Glue: A Complete Guide

The global laminating machine market is projected to witness a steady growth in the coming years, driven by the increasing demand for efficient and high-quality laminating solutions across various industries. One of the key players in this market is a leading company that specializes in the manufacturing and supply of cutting-edge laminating machinery. Their latest offering, the Vertical/White Glue Laminating Machine, has been making waves in the industry for its innovative features and superior performance.The Vertical/White Glue Laminating Machine is designed to meet the diverse needs of customers looking for a reliable and versatile laminating solution. With its advanced technology and precision engineering, this machine is capable of delivering consistent and high-quality laminating results, making it the ideal choice for businesses operating in the packaging, printing, and publishing sectors.One of the standout features of the Vertical/White Glue Laminating Machine is its ability to handle a wide range of materials, including paper, cardboard, and plastic. This makes it a highly adaptable solution for businesses looking to streamline their laminating processes and improve overall operational efficiency. Additionally, the machine is equipped with state-of-the-art automation and control systems, allowing for seamless operation and minimal downtime.The company behind the Vertical/White Glue Laminating Machine has a longstanding reputation for delivering cutting-edge solutions that are tailored to meet the unique needs of their customers. With a strong focus on innovation and quality, they have consistently set industry benchmarks and have earned the trust of businesses worldwide.In addition to their commitment to excellence, the company also prides itself on its dedication to sustainability and environmental responsibility. The Vertical/White Glue Laminating Machine is designed with energy efficiency and minimal environmental impact in mind, aligning with the company's goal of providing sustainable solutions for the future.With a global presence and a strong network of distributors and partners, the company is well-positioned to meet the growing demand for laminating machinery across various industries. Their Vertical/White Glue Laminating Machine has already garnered positive feedback from customers who have praised its performance, reliability, and ease of use.As the global market for laminating machinery continues to expand, the Vertical/White Glue Laminating Machine is poised to make a significant impact, offering businesses a competitive edge through its superior capabilities and advanced features. With a track record of delivering innovative solutions and a commitment to customer satisfaction, the company is set to lead the way in the laminating machinery market for years to come.In conclusion, the Vertical/White Glue Laminating Machine is a testament to the company's dedication to delivering cutting-edge solutions that meet the evolving needs of the industry. With its advanced technology, versatile capabilities, and commitment to sustainability, this machine is set to redefine the standards for laminating machinery and solidify the company's position as a leader in the global market.

Top 5 Mat Laminating Machines for Your Business Needs

The Mat Laminating Machine is a versatile and powerful piece of equipment that has the ability to revolutionize the way businesses and individuals preserve and protect their printed materials. This state-of-the-art machine, developed and manufactured by a leading company in the printing and laminating industry, is designed to provide users with a reliable and efficient solution for laminating a wide range of materials, including paper, cardstock, photographs, posters, and more.The company behind the innovative Mat Laminating Machine has a long-standing reputation for producing high-quality printing and laminating equipment that meets the needs of businesses and individuals alike. With a commitment to excellence and a dedication to staying ahead of the curve in terms of technological advancements, the company has become a trusted name in the industry.The Mat Laminating Machine is a testament to the company's dedication to innovation and customer satisfaction. With its advanced features and user-friendly design, this machine is capable of delivering professional-quality lamination results with ease. Whether it's for personal use, small businesses, or large-scale operations, the Mat Laminating Machine is a valuable asset that can streamline the lamination process and improve overall productivity.One of the standout features of the Mat Laminating Machine is its ability to provide a matte finish to laminated materials. This feature sets it apart from other laminating machines on the market, as it allows users to achieve a smooth, non-reflective finish that is ideal for a variety of applications. From creating professional-looking documents to preserving photographs and artwork, the matte finish produced by the Mat Laminating Machine adds a touch of sophistication and durability to any laminated material.Additionally, the machine is equipped with cutting-edge technology that ensures consistent and precise lamination results. The adjustable settings and intuitive controls make it easy for users to customize the laminating process to suit their specific needs, while the high-speed operation ensures that jobs are completed quickly and efficiently. With the ability to handle various thicknesses and sizes of materials, the Mat Laminating Machine offers exceptional versatility and flexibility.Furthermore, the company takes pride in providing exceptional customer support and service. From initial inquiries to ongoing technical assistance, the company's dedicated team is committed to helping customers make the most of their investment in the Mat Laminating Machine. In addition to offering top-notch equipment, the company understands the importance of building lasting relationships with its customers, and strives to be a reliable partner in their success.The Mat Laminating Machine is a game-changer in the printing and laminating industry, and its impact is being felt by businesses and individuals around the world. With its innovative features, reliable performance, and outstanding customer support, this machine has earned its reputation as a top choice for those looking to take their laminating capabilities to the next level. As the company continues to push the boundaries of what is possible in the printing and laminating industry, the Mat Laminating Machine stands as a testament to their commitment to excellence and innovation.

Durable and Efficient Laminating Machine for Leather Goods

Laminating Machine For Leather, a Cutting-Edge Innovation in Leather ManufacturingLaminating machine for leather has been increasingly recognized as a cutting-edge innovation in the leather manufacturing industry. This innovative technology has revolutionized the process of laminating leather, making it more efficient and precise than ever before. With the use of advanced machinery and technology, companies have been able to improve the quality and durability of leather products while reducing production costs.One company that has been at the forefront of this technological advancement is {}. With a strong focus on research and development, the company has been able to create state-of-the-art laminating machines for leather that have been widely recognized for their efficiency and reliability. By combining intelligent technology with an in-depth understanding of the needs of the leather industry, {} has successfully developed a range of laminating machines that have set a new standard in the industry.Established in {}, {} has grown to become a leading manufacturer of industrial machinery for the leather industry. With a strong commitment to innovation and quality, the company has continuously invested in research and development to create cutting-edge solutions for leather processing. With a team of highly skilled engineers and technicians, {} has been able to develop a range of laminating machines that have been widely adopted by leather manufacturers around the world.The laminating machine for leather developed by {} is designed to provide a seamless and efficient lamination process for a wide range of leather products. Whether it is for footwear, leather goods, or automotive applications, the machine is capable of laminating different types of leather with precision and consistency. By integrating advanced control systems and innovative technology, the machine is able to deliver high-quality laminated leather that meets the most demanding industry standards.One of the key features of the {} laminating machine is its ability to handle a variety of leather materials, including natural leather, synthetic leather, and suede. The machine is equipped with precision rollers and advanced heating systems that ensure an even lamination process, resulting in a smooth and uniform finish. Additionally, the machine is designed to be highly versatile, allowing for customization and flexibility to meet the specific needs of different leather manufacturers.The use of {} laminating machine has enabled leather manufacturers to significantly improve their production efficiency and output quality. By streamlining the lamination process, the machine has helped companies reduce material waste and labor costs, while increasing the overall productivity of their operations. Furthermore, the machine's ability to deliver consistent lamination results has helped manufacturers enhance the quality and performance of their leather products, ultimately leading to greater customer satisfaction and market competitiveness.In addition to its technological innovation, {} has also established a strong reputation for its commitment to customer service and support. With a global network of sales and service partners, the company has been able to provide comprehensive assistance to its customers, ensuring that their laminating machines are always operating at peak performance. Whether it is through technical training, maintenance services, or spare parts supply, {} is dedicated to supporting its customers and helping them achieve the best possible results with their laminating machines.Looking ahead, the future of laminating machine for leather looks promising, with continued advancements in technology and machinery. With companies like {} leading the way in innovation, the leather manufacturing industry can expect to see further improvements in the efficiency, quality, and sustainability of leather production. As the demand for high-quality leather products continues to grow, the role of advanced laminating machines will become increasingly vital in meeting the needs of manufacturers and consumers alike.

High-Quality Industrial Laminating Machine for SBR Materials

SBR Laminating Machine is a revolutionary new product that is set to change the way that laminating is done in the industry. This cutting-edge piece of equipment is designed to streamline the laminating process, making it more efficient and cost-effective for businesses of all sizes. The SBR Laminating Machine is the result of years of research and development, and it promises to deliver exceptional results for those in need of high-quality lamination.The SBR Laminating Machine is a high-speed laminator that is capable of laminating a wide variety of materials, including paper, cardstock, and even certain types of fabric. This versatility makes it an ideal choice for businesses that need to laminate a wide range of items, from business cards to banners. The machine is designed to be easy to operate, with a user-friendly interface that allows for quick and simple adjustments to be made as needed. This means that businesses can save time and money by streamlining their laminating processes and reducing the need for manual labor.In addition to its speed and versatility, the SBR Laminating Machine is also known for its exceptional quality and durability. The machine is built to last, with a sturdy construction that can withstand the rigors of regular use. This means that businesses can rely on the SBR Laminating Machine to deliver consistent, high-quality results time after time. Furthermore, the machine is designed for minimal maintenance, which further reduces the overall cost of ownership for businesses.One of the key features of the SBR Laminating Machine is its advanced technology, which allows for precise and efficient lamination. The machine utilizes state-of-the-art sensors and controls to ensure that each item is laminated to the highest standard. This means that businesses can trust the SBR Laminating Machine to deliver professional-looking results, whether they are laminating a single item or a large batch of materials. Additionally, the machine is designed to be energy-efficient, which helps to reduce the overall environmental impact of the laminating process.The company behind the SBR Laminating Machine is known for its commitment to excellence and innovation in the field of lamination. With years of experience in the industry, the company has developed a reputation for delivering exceptional products that meet the needs of businesses across a wide range of industries. The SBR Laminating Machine is the latest example of this commitment, and it is set to become an indispensable tool for businesses looking to streamline their lamination processes.In addition to the SBR Laminating Machine, the company also offers a range of other lamination products and services, including laminating film, pouches, and accessories. This means that businesses can rely on the company for all of their laminating needs, from the purchase of a new machine to the ongoing supply of consumables. With a focus on customer satisfaction and support, the company is dedicated to helping businesses achieve the best possible results with their lamination processes.Overall, the SBR Laminating Machine is set to revolutionize the way that businesses approach lamination. With its speed, versatility, quality, and advanced technology, the machine is a game-changer for businesses of all sizes. And with the backing of a reputable and innovative company, businesses can trust that they are investing in a product that will deliver exceptional results for years to come. As the SBR Laminating Machine continues to gain traction in the industry, businesses are sure to benefit from its many advantages.