High-Quality Laminating Equipment Manufactured in China - A Game Changer in the Industry

By:Admin

In the world of industrial machinery and equipment, Chinese manufacturing has become synonymous with high quality and cost-effectiveness. One company that has exemplified this reputation is (remove brand name), a leading manufacturer of laminating equipment made in China. (remove brand name) has been at the forefront of the industry for many years, consistently delivering top-notch products to their clients all over the world.

Established in 2005, (remove brand name) has rapidly grown to become a trusted name in the field of laminating equipment manufacturing. With a state-of-the-art production facility in China, the company has the capability to produce a wide range of laminating machines that cater to the diverse needs of its global clientele. (remove brand name) prides itself on its commitment to innovation, quality, and customer satisfaction, which has been key to its success over the years.

One of the company's strengths lies in its ability to leverage advanced technology and cutting-edge manufacturing processes to develop laminating equipment that is both durable and efficient. By investing in research and development, (remove brand name) has been able to stay ahead of the curve in terms of innovation, ensuring that its products are always at the forefront of industry standards.

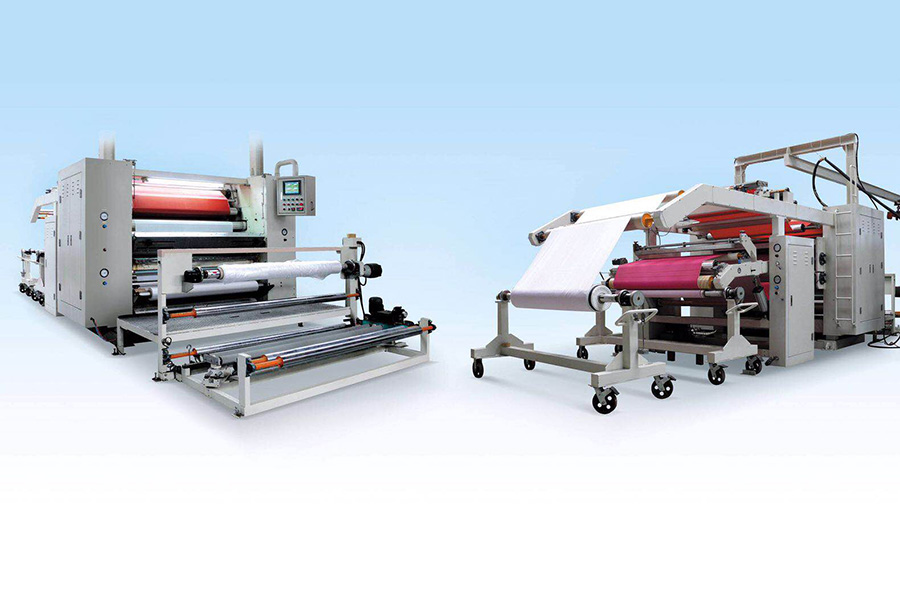

The range of laminating equipment offered by (remove brand name) caters to a wide spectrum of industries, including printing, packaging, and graphics. Whether it's roll-to-roll laminators, thermal laminators, or wide format laminators, the company's product portfolio is designed to meet the specific requirements of its clients, regardless of their scale of operation.

In addition to its commitment to product excellence, (remove brand name) places a strong emphasis on customer service and support. The company understands that its clients rely on their equipment to deliver consistent performance, which is why it offers comprehensive after-sales services to ensure that their needs are met even after the sale has been completed. By providing timely maintenance, repairs, and technical support, (remove brand name) has been able to build long-lasting relationships with its customers, earning their trust and loyalty.

As part of its global expansion strategy, (remove brand name) has established a strong presence in international markets, with a dedicated network of distributors and partners across the world. This has allowed the company to penetrate new territories and reach a wider audience, further solidifying its position as a leading supplier of laminating equipment on a global scale.

Furthermore, (remove brand name) has been proactive in its efforts to align its operations with international quality and safety standards. The company holds various certifications and accreditations, ensuring that its products meet the stringent requirements of different regulatory bodies. This commitment to quality assurance has been a key factor in building trust and confidence in (remove brand name) among its customers.

Looking ahead, (remove brand name) is poised to continue its trajectory of growth and innovation, with a keen focus on expanding its product range and reaching new markets. By leveraging its expertise in manufacturing and its dedication to customer satisfaction, the company aims to further solidify its position as a global leader in the laminating equipment industry.

In conclusion, (remove brand name) exemplifies the sophistication and quality of laminating equipment made in China. With its unwavering commitment to excellence, innovation, and customer satisfaction, the company has successfully established itself as a premier provider of laminating solutions on a global scale. As it continues to expand its reach and enhance its product offerings, (remove brand name) is set to remain a driving force in the industry for years to come.

Company News & Blog

Highly Efficient Dual-Use Laminating Machine for Various Applications

Dual-Use Laminating Machine: A Revolutionary Innovation in the Laminating IndustryIn recent years, the laminating industry has witnessed a significant transformation with the introduction of the Dual-Use Laminating Machine. This innovative technology has revolutionized the laminating process by providing users with a versatile and efficient solution for their laminating needs. The Dual-Use Laminating Machine is a breakthrough in the industry, offering a wide range of applications and benefits for both personal and professional use.{Company Name} is the pioneering force behind the Dual-Use Laminating Machine, and they have made significant strides in the laminating industry with its cutting-edge technology. With a strong commitment to innovation and excellence, {Company Name} has developed the Dual-Use Laminating Machine to meet the evolving needs of the market and provide users with a superior laminating experience.One of the key features that set the Dual-Use Laminating Machine apart from traditional laminating machines is its dual functionality. This innovative machine is designed to handle both cold and hot lamination, making it incredibly versatile and suitable for a wide range of laminating applications. Whether users need to laminate documents, photos, artwork, or other materials, the Dual-Use Laminating Machine provides a seamless and high-quality lamination process for all their needs.Moreover, the Dual-Use Laminating Machine offers users the flexibility to choose between different lamination settings, allowing them to customize their lamination experience based on the type of material they are working with. With adjustable temperature settings and other customizable features, users can achieve the perfect lamination results with ease and precision.Another standout feature of the Dual-Use Laminating Machine is its user-friendly design. {Company Name} has prioritized user experience in the development of this technology, ensuring that the machine is intuitive and easy to operate for users of all skill levels. The machine is equipped with simple controls and clear instructions, making the lamination process straightforward and efficient for everyone.In addition to its advanced features, the Dual-Use Laminating Machine is also known for its high-speed performance and exceptional lamination quality. This machine is capable of delivering fast and reliable lamination results without compromising on the quality of the finished product. Whether users are working on a large volume of lamination projects or require precise and professional results, the Dual-Use Laminating Machine is up to the task.Aside from its impressive performance, the Dual-Use Laminating Machine is also designed with durability and longevity in mind. {Company Name} has engineered this machine using high-quality materials and advanced manufacturing techniques to ensure its long-term reliability and sustainability. As a result, users can count on the Dual-Use Laminating Machine to deliver consistent and top-notch lamination results for years to come.The introduction of the Dual-Use Laminating Machine has been met with widespread acclaim and positive feedback from both industry professionals and individual users. Many have praised the machine for its unparalleled versatility, efficiency, and user-friendly design, making it a standout innovation in the laminating industry.Overall, the Dual-Use Laminating Machine represents a significant advancement in the laminating industry, offering users a comprehensive solution for their lamination needs. With its dual functionality, user-friendly design, high-speed performance, and exceptional quality, this innovative machine has set a new standard for lamination technology and has quickly become a go-to choice for many professionals and enthusiasts alike.As {Company Name} continues to drive innovation in the laminating industry, the Dual-Use Laminating Machine stands as a testament to their commitment to excellence and their dedication to providing users with best-in-class solutions for their lamination needs. With its remarkable features and unmatched performance, this revolutionary machine is sure to leave a lasting impact on the industry and redefine the way users approach laminating.

Powerful and Durable Laminating Machine for Strong Glue Applications

The leading provider of advanced machinery and equipment, (), has recently unveiled its latest innovation in the form of the Strong Glue Laminating Machine. This cutting-edge machine is set to revolutionize the lamination process with its advanced features and innovative technology.With a strong focus on precision and efficiency, the Strong Glue Laminating Machine is designed to meet the growing demand for high-quality lamination in various industries, including packaging, printing, and manufacturing. This state-of-the-art machine is capable of applying a strong and durable adhesive to a wide range of materials, including paper, cardboard, and plastic, making it an ideal solution for businesses looking to enhance the durability and visual appeal of their products.The Strong Glue Laminating Machine is equipped with advanced technology that ensures a precise and uniform application of adhesive, resulting in a flawless lamination finish. This not only improves the overall quality of the end product but also increases production efficiency by reducing waste and rework. Additionally, the machine is designed to be easy to operate, making it suitable for businesses of all sizes.In addition to its advanced features, the Strong Glue Laminating Machine is also built with durability and reliability in mind. With a robust construction and high-quality components, this machine is built to withstand the rigors of continuous use in a demanding production environment. This ensures that businesses can rely on the machine to deliver consistent performance and lasting value for years to come.The release of the Strong Glue Laminating Machine is a testament to ()'s commitment to innovation and excellence in the field of machinery and equipment. With a proven track record of delivering cutting-edge solutions to its customers, () has established itself as a trusted partner for businesses looking to stay ahead in today's competitive market.As a company, () is dedicated to providing best-in-class machinery and equipment that meet the evolving needs of modern industries. With a focus on research and development, the company constantly strives to push the boundaries of innovation and deliver solutions that drive productivity, efficiency, and quality for its customers.With the introduction of the Strong Glue Laminating Machine, () is once again demonstrating its ability to anticipate market needs and deliver solutions that exceed expectations. This machine is set to make a significant impact on the lamination process, empowering businesses to achieve new levels of performance and success.The launch of the Strong Glue Laminating Machine marks a new chapter in ()'s journey to lead the way in the machinery and equipment industry. With its advanced technology, robust construction, and user-friendly design, this machine is set to become an indispensable tool for businesses looking to elevate their lamination capabilities and gain a competitive edge in the market.In conclusion, the introduction of the Strong Glue Laminating Machine from () is a game-changer for businesses seeking to enhance their lamination process. With its advanced features and reliable performance, this machine is set to redefine the standards of lamination excellence and empower businesses to achieve new levels of productivity and success. As () continues to push the boundaries of innovation, the company remains at the forefront of delivering cutting-edge solutions that drive growth and success for its customers.

How to Use a PVC Ceiling Lamination Machine for a Smooth and Professional Finish

Pvc Ceiling Lamination Machine Revolutionizes Production Process at Leading Manufacturing CompanyThe manufacturing industry is constantly evolving and seeking innovative solutions to enhance production processes. Leading the way in this pursuit is the renowned company, a global leader in manufacturing high-quality PVC ceiling products. With a strong focus on technology and innovation, has recently introduced a groundbreaking PVC Ceiling Lamination Machine that is set to revolutionize the production process.The PVC Ceiling Lamination Machine is a state-of-the-art piece of equipment designed to enhance efficiency, productivity, and overall product quality. This cutting-edge machine is equipped with advanced features and capabilities that set it apart from traditional lamination machines, making it a game-changer in the industry.One of the key highlights of this innovative machine is its ability to laminate PVC ceiling panels with precision and speed. The machine is designed to handle a wide range of panel sizes and thicknesses, making it highly versatile for various production needs. Its high-speed lamination capabilities significantly reduce production time, allowing for increased output and improved efficiency.Furthermore, the PVC Ceiling Lamination Machine is equipped with advanced automation technology that streamlines the entire lamination process. This not only minimizes the need for manual intervention but also ensures a consistently high level of quality in the finished products. The machine's automated features also contribute to reducing production costs and preventing wastage, marking a significant advancement in sustainable manufacturing practices.In addition to its advanced capabilities, the PVC Ceiling Lamination Machine is designed for user-friendly operation, making it accessible to a wide range of manufacturing professionals. Its intuitive interface and controls allow for easy setup and operation, while its robust construction ensures durability and reliability for long-term use.The introduction of this cutting-edge machine underscores 's commitment to staying at the forefront of technological advancements in the manufacturing industry. By investing in state-of-the-art equipment and embracing innovation, the company continues to set new standards for product quality, efficiency, and sustainability."We are thrilled to introduce the PVC Ceiling Lamination Machine as a testament to our ongoing dedication to innovation and excellence in manufacturing," said [Company Spokesperson]. "This advanced machine will not only enhance our production capabilities but also enable us to deliver superior quality products to our customers more efficiently than ever before."The PVC Ceiling Lamination Machine is set to have a significant impact on 's production operations, with the potential to increase output, reduce lead times, and elevate product quality. As a leader in the manufacturing industry, the company's adoption of this innovative technology further solidifies its position as a driving force for progress and innovation.Looking ahead, is poised to continue driving innovation in the manufacturing of PVC ceiling products, with a strong emphasis on leveraging advanced technology to propel its operations forward. With the introduction of the PVC Ceiling Lamination Machine, the company is well-positioned to set new benchmarks for efficiency, productivity, and quality in the industry.As the manufacturing landscape continues to evolve, remains committed to staying ahead of the curve and delivering unparalleled value to its customers through cutting-edge technology and innovation. The introduction of the PVC Ceiling Lamination Machine serves as a testament to the company's unwavering commitment to pushing the boundaries of what is possible in modern manufacturing.

High-Quality Industrial Laminating Machine for SBR Materials

SBR Laminating Machine is a revolutionary new product that is set to change the way that laminating is done in the industry. This cutting-edge piece of equipment is designed to streamline the laminating process, making it more efficient and cost-effective for businesses of all sizes. The SBR Laminating Machine is the result of years of research and development, and it promises to deliver exceptional results for those in need of high-quality lamination.The SBR Laminating Machine is a high-speed laminator that is capable of laminating a wide variety of materials, including paper, cardstock, and even certain types of fabric. This versatility makes it an ideal choice for businesses that need to laminate a wide range of items, from business cards to banners. The machine is designed to be easy to operate, with a user-friendly interface that allows for quick and simple adjustments to be made as needed. This means that businesses can save time and money by streamlining their laminating processes and reducing the need for manual labor.In addition to its speed and versatility, the SBR Laminating Machine is also known for its exceptional quality and durability. The machine is built to last, with a sturdy construction that can withstand the rigors of regular use. This means that businesses can rely on the SBR Laminating Machine to deliver consistent, high-quality results time after time. Furthermore, the machine is designed for minimal maintenance, which further reduces the overall cost of ownership for businesses.One of the key features of the SBR Laminating Machine is its advanced technology, which allows for precise and efficient lamination. The machine utilizes state-of-the-art sensors and controls to ensure that each item is laminated to the highest standard. This means that businesses can trust the SBR Laminating Machine to deliver professional-looking results, whether they are laminating a single item or a large batch of materials. Additionally, the machine is designed to be energy-efficient, which helps to reduce the overall environmental impact of the laminating process.The company behind the SBR Laminating Machine is known for its commitment to excellence and innovation in the field of lamination. With years of experience in the industry, the company has developed a reputation for delivering exceptional products that meet the needs of businesses across a wide range of industries. The SBR Laminating Machine is the latest example of this commitment, and it is set to become an indispensable tool for businesses looking to streamline their lamination processes.In addition to the SBR Laminating Machine, the company also offers a range of other lamination products and services, including laminating film, pouches, and accessories. This means that businesses can rely on the company for all of their laminating needs, from the purchase of a new machine to the ongoing supply of consumables. With a focus on customer satisfaction and support, the company is dedicated to helping businesses achieve the best possible results with their lamination processes.Overall, the SBR Laminating Machine is set to revolutionize the way that businesses approach lamination. With its speed, versatility, quality, and advanced technology, the machine is a game-changer for businesses of all sizes. And with the backing of a reputable and innovative company, businesses can trust that they are investing in a product that will deliver exceptional results for years to come. As the SBR Laminating Machine continues to gain traction in the industry, businesses are sure to benefit from its many advantages.

Advanced Lamination Machines for Efficient Production

In an ever-evolving world, industries are constantly striving to innovate and adapt to meet the needs of their customers. One such company that has been at the forefront of this evolution is {company name}. With a rich history of providing cutting-edge technology and exceptional customer service, {company name} has once again raised the bar with their latest innovation - the Macchine Per La Laminazione.The Macchine Per La Laminazione is a state-of-the-art laminating machine that is designed to meet the increasing demand for high-quality laminated products. Whether it is for packaging, graphic arts, or industrial applications, this machine is poised to revolutionize the laminating process. With its advanced features and superior performance, the Macchine Per La Laminazione is set to become the industry standard for laminating machines.One of the key features of the Macchine Per La Laminazione is its versatility. It is capable of laminating a wide range of materials, including paper, cardboard, plastic, and metal. This means that customers can use this machine for a variety of applications, making it a valuable investment for businesses across different industries. Additionally, the Macchine Per La Laminazione offers precise control over the laminating process, ensuring that the end product meets the highest standards of quality.Another notable aspect of the Macchine Per La Laminazione is its efficiency. By streamlining the laminating process, this machine can significantly increase productivity, allowing businesses to meet tight deadlines and handle high-volume orders with ease. Furthermore, the Macchine Per La Laminazione is designed with user-friendly features, making it easy for operators to set up and run the machine. This not only saves time but also reduces the risk of errors, ensuring that the laminating process runs smoothly and efficiently.The Macchine Per La Laminazione is also built with durability in mind. With its robust construction and high-quality components, this machine is designed to withstand the rigors of daily use. This means that businesses can rely on the Macchine Per La Laminazione to deliver consistent and reliable performance, day in and day out. Moreover, the machine is backed by {company name}'s commitment to customer satisfaction, providing businesses with the peace of mind that they are investing in a product that will deliver long-term value.In addition to its impressive technical specifications, the Macchine Per La Laminazione is also environmentally friendly. It is designed to minimize waste and energy consumption, making it a sustainable choice for businesses looking to reduce their environmental footprint. By investing in the Macchine Per La Laminazione, companies can demonstrate their commitment to sustainability while reaping the benefits of improved efficiency and productivity.Overall, the Macchine Per La Laminazione is a testament to {company name}'s dedication to innovation and excellence. With its advanced features, superior performance, and commitment to sustainability, this machine is set to redefine the laminating process and set new standards for the industry. As businesses continue to seek ways to stay ahead of the curve, the Macchine Per La Laminazione presents an opportunity for them to enhance their operations and deliver exceptional laminated products to their customers.In conclusion, the introduction of the Macchine Per La Laminazione is a significant milestone for {company name}. It represents their unwavering commitment to providing customers with the best-in-class solutions and demonstrates their ability to anticipate and meet the evolving needs of the industry. As the market for laminated products continues to grow, businesses can rely on the Macchine Per La Laminazione to help them stay competitive and deliver exceptional results. With its cutting-edge technology, versatility, efficiency, and sustainability, this machine is poised to make a lasting impact on the industry and further solidify {company name}'s reputation as a leader in the field.

High Quality Fiberglass Cloth Laminating Machine: Everything You Need to Know

Fiberglass Cloth Laminating Machine Advances Manufacturing CapabilitiesIn an age where technological advancements continue to revolutionize various industries, the manufacturing sector is no exception. With a commitment to innovation and efficiency, {Company Name} has recently introduced a state-of-the-art Fiberglass Cloth Laminating Machine to enhance its production capabilities.{Company Name} is a leading manufacturer specializing in the production of fiberglass cloth and composite materials. With a strong focus on quality and precision, the company has established itself as a trusted supplier to a diverse range of industries, including aerospace, automotive, marine, and construction.The new Fiberglass Cloth Laminating Machine represents a significant investment in modernizing the company's manufacturing processes. This cutting-edge equipment is designed to streamline the lamination of fiberglass cloth with various resin systems, allowing for greater customization and flexibility in meeting customer requirements. By integrating advanced automation and control systems, {Company Name} aims to significantly improve production efficiency while maintaining its high standards of product quality.One of the key features of the new machine is its ability to handle a wide range of fiberglass cloth weights and widths, providing versatility in catering to different application needs. This flexibility is crucial in serving the diverse demands of {Company Name}’s customer base, as it allows for the production of custom composite materials tailored to specific performance and design specifications.Moreover, the Fiberglass Cloth Laminating Machine is equipped with advanced temperature and pressure control systems, ensuring optimal processing conditions for different resin types. This level of precision in lamination is essential for achieving consistent product quality and performance, which are paramount in the industries {Company Name} serves."We are thrilled to introduce this cutting-edge Fiberglass Cloth Laminating Machine to our manufacturing facility," stated [Spokesperson Name], [Title] at {Company Name}. "This investment reflects our commitment to staying at the forefront of technology in order to better serve our customers. With this new equipment, we are confident in our ability to deliver even higher quality composite materials with shorter lead times."The introduction of the Fiberglass Cloth Laminating Machine is also in line with {Company Name}’s dedication to environmental sustainability. By optimizing production processes and minimizing material waste, the company aims to reduce its environmental footprint while enhancing operational efficiency. The new machine's advanced features contribute to the achievement of these objectives by reducing energy consumption and material usage during the lamination process.As {Company Name} continues to expand its presence in the global market, the addition of the Fiberglass Cloth Laminating Machine positions the company as a leading provider of advanced composite materials. The enhanced manufacturing capabilities afforded by this state-of-the-art equipment further solidify {Company Name}’s reputation for excellence and innovation within the industry.With a focus on pushing the boundaries of what is possible in composite material manufacturing, {Company Name} remains dedicated to meeting the evolving needs of its customers. The introduction of the Fiberglass Cloth Laminating Machine marks a significant milestone in the company's journey towards continued growth and technological advancement.In conclusion, the unveiling of the Fiberglass Cloth Laminating Machine underscores {Company Name}’s commitment to delivering superior quality composite materials while embracing innovation and sustainability. With this advanced equipment in place, {Company Name} is poised to set new standards in the industry and solidify its position as a preferred supplier of fiberglass cloth and composite materials for a wide range of applications.

High-quality Suede Fabric Laminating Machine for Efficient Production

Suede Fabric Laminating Machine Revolutionizes Textile IndustryInnovations in the textile industry have always been at the forefront of creating new and improved materials for various applications. With an increasing demand for high-quality fabrics, the need for advanced machinery to produce these fabrics has become a necessity. This is where the Suede Fabric Laminating Machine comes into play, revolutionizing the way suede fabrics are created and laminated.The Suede Fabric Laminating Machine, produced by a leading machinery manufacturer, is designed to provide a seamless process for laminating suede fabrics. This machine offers a range of features and capabilities that set it apart from traditional laminating machines. With its advanced technology and precision engineering, this machine is poised to transform the textile industry.The company behind the Suede Fabric Laminating Machine is a global leader in the design and manufacturing of cutting-edge machinery for the textile industry. With a strong focus on innovation and quality, they have become a trusted name in the industry, providing solutions to meet the evolving needs of textile manufacturers worldwide. Their commitment to excellence and customer satisfaction has earned them a reputation as a reliable partner for textile companies seeking to enhance their production capabilities.The Suede Fabric Laminating Machine is a testament to the company's dedication to innovation. It is equipped with state-of-the-art technology that allows for precise lamination of suede fabrics, resulting in a superior end product. The machine's user-friendly interface and intuitive controls make it easy to operate, while its efficient design ensures maximum productivity and minimal downtime.One of the key features of the Suede Fabric Laminating Machine is its ability to achieve consistent and uniform lamination of suede fabrics. This is essential for ensuring the quality and durability of the final product, as well as for meeting the strict requirements of textile manufacturers and their customers. The machine's advanced lamination process also reduces waste and improves efficiency, ultimately lowering production costs for manufacturers.Furthermore, the Suede Fabric Laminating Machine is designed to handle a wide range of suede fabrics, including different thicknesses and compositions. This versatility makes it a valuable asset for textile manufacturers who produce a variety of suede products, from clothing and accessories to upholstery and footwear. The machine's ability to accommodate diverse fabric types and specifications sets it apart from other laminating machines on the market.In addition to its advanced lamination capabilities, the Suede Fabric Laminating Machine is also designed for durability and reliability. Its robust construction and high-quality components ensure long-term performance, even in demanding production environments. This reliability is crucial for textile manufacturers who depend on their machinery to maintain consistent quality and meet production deadlines.The introduction of the Suede Fabric Laminating Machine represents a significant advancement in the textile industry. Its innovative technology, superior performance, and versatility make it an invaluable asset for manufacturers looking to enhance their production processes and deliver high-quality suede fabrics to the market. With the support of the company's expertise and dedication to excellence, this machine is set to become a game-changer for the textile industry, setting new standards for quality and efficiency in suede fabric manufacturing.

High-quality Laminating Machine for Efficient Document Protection

Eva Laminating Machine Enhances Product Quality and Efficiency for Global Packaging CompanyIn the competitive world of packaging, the quality and efficiency of production are essential for success. This is why the global packaging company {company name} has recently invested in state-of-the-art Eva Laminating Machine to enhance their product quality and efficiency.{Company name} has been a leader in the packaging industry for over 20 years, providing innovative and sustainable packaging solutions to a wide range of industries including food and beverage, pharmaceuticals, and consumer goods. With a commitment to continuous improvement and investment in cutting-edge technology, the company has been able to stay ahead of the competition and meet the evolving needs of their customers.The recent addition of the Eva Laminating Machine is an example of {company name}'s dedication to staying at the forefront of packaging technology. This advanced machine is capable of laminating various types of materials, such as paper, film, and foil, to create high-quality packaging products with enhanced barrier properties, heat resistance, and visual appeal.The Eva Laminating Machine offers several key advantages that have already had a significant impact on {company name}'s operations. The machine is equipped with precision temperature and pressure control systems, ensuring consistent lamination results and minimizing material waste. Its high-speed capabilities also enable faster production cycles, allowing {company name} to meet tight deadlines and customer demands more efficiently.Furthermore, the Eva Laminating Machine's versatility allows {company name} to offer a wider range of packaging solutions to their clients. Whether it's for food packaging that requires excellent barrier properties, pharmaceutical packaging that demands strict hygiene standards, or high-end consumer goods that rely on attractive visual effects, the Eva Laminating Machine can handle it all.In addition to its technical capabilities, the Eva Laminating Machine is also designed with sustainability in mind. It uses eco-friendly adhesives and solvents, minimizing the environmental impact of the lamination process. This aligns with {company name}'s commitment to sustainability and corporate social responsibility, and has been well-received by customers who are increasingly looking for eco-friendly packaging solutions.{Company name} is excited about the possibilities that the Eva Laminating Machine brings to their business. "The investment in this advanced lamination technology has already proven to be a game-changer for us," says CEO {CEO name}. "The Eva Laminating Machine has allowed us to elevate the quality of our packaging products while improving our production efficiency, enabling us to better serve our customers' needs."{Company name} plans to leverage the capabilities of the Eva Laminating Machine to explore new market opportunities and expand their product offerings. With this cutting-edge technology in their arsenal, they are confident in their ability to continue providing innovative and sustainable packaging solutions to their global customer base.Overall, the investment in the Eva Laminating Machine represents a significant step forward for {company name}. By combining advanced technology with their industry expertise, {company name} is well-positioned to maintain their leadership in the packaging industry and provide their customers with the highest quality products and services.

Discover the Versatility and Benefits of Pe Foam Sheet Laminating Machines

Title: Cutting-Edge PE Foam Sheet Laminating Machine Revolutionizes Packaging IndustryIntroduction:In an era driven by technological advancements, the packaging industry is witnessing a transformative breakthrough in the form of the PE Foam Sheet Laminating Machine. Engineered with precision and efficiency, this state-of-the-art machine is poised to usher in a new era of productivity and versatility for packaging manufacturers across the globe.With the ever-growing demand for eco-friendly and sustainable packaging materials, the introduction of the PE Foam Sheet Laminating Machine couldn't have been timelier. This cutting-edge technology offers tangible benefits to both manufacturers and consumers, making it an indispensable tool in the packaging industry.Advanced Features and Capabilities:The PE Foam Sheet Laminating Machine incorporates a range of advanced features that set it apart from conventional laminating machines. Its precision engineering ensures a seamless integration of different layers while maintaining the foam sheet's structural integrity. The machine is equipped with automatic feeding and cutting mechanisms, reducing human intervention and maximizing productivity.Additionally, the PE Foam Sheet Laminating Machine offers unmatched versatility. It can efficiently laminate various materials, including paper, plastic films, aluminum foil, and fabric. This flexibility allows manufacturers to create customized packaging solutions for a wide range of industries, including food and beverage, electronics, healthcare, and logistics.Improved Efficiency and Cost-Effectiveness:By automating the lamination process, the PE Foam Sheet Laminating Machine significantly improves operational efficiency. The seamless integration of multiple layers minimizes wastage while reducing production time considerably. As a result, manufacturers can meet market demands promptly and maximize their overall output.Furthermore, the machine's high-speed lamination capabilities enable manufacturers to streamline their production line, reducing labor costs and increasing profitability. The automation-driven workflow also minimizes human errors, ensuring consistent and reliable output, leading to greater customer satisfaction.Eco-Friendly Packaging Solution:The PE Foam Sheet Laminating Machine plays a crucial role in sustainable packaging practices. The ability to laminate various materials allows manufacturers to create eco-friendly packaging solutions by incorporating recyclable or biodegradable materials. This contributes to reducing carbon footprints and plastic waste, aligning with global efforts towards a cleaner and greener planet.End-User Benefits:The advancements in foam sheet lamination technology directly translate to advantages for end-users. The high-quality lamination ensures enhanced protection for the packaged goods, safeguarding them from external factors like moisture, temperature variations, and impacts. The durability of the laminated foam sheets also allows for increased reusability, addressing consumer concerns regarding sustainability.Market Outlook and Growth Potential:As the packaging industry continues to undergo rapid growth, the demand for advanced laminating solutions is on the rise. The PE Foam Sheet Laminating Machine provides manufacturers with a competitive edge by enabling them to deliver superior-quality packaging materials while optimizing production costs.Key players in the packaging industry are increasingly adopting this revolutionary technology, thus driving market growth. Moreover, the increased focus on sustainable and eco-friendly practices is projected to further boost the demand for the PE Foam Sheet Laminating Machine in the coming years.Conclusion:With its advanced features, improved efficiency, and environmentally-friendly nature, the PE Foam Sheet Laminating Machine is set to redefine the packaging industry. Apart from bolstering operational capabilities, this cutting-edge technology ensures the production of high-quality, customized packaging materials that cater to the evolving needs of end-users.As manufacturers embrace sustainability and adapt to market demands, the PE Foam Sheet Laminating Machine provides an invaluable solution for creating innovative, durable, and eco-friendly packaging solutions. With its immense growth potential, this technology is poised to become a game-changer in the ever-evolving packaging industry.

Top Thermal Laminating Machine Manufacturers in the Market

Thermal laminating machines are an essential tool for businesses and organizations looking to protect and preserve important documents and materials. These machines are used to apply a thin layer of plastic film to paper or other materials, creating a durable and professional-looking finish. As the demand for thermal laminating machines continues to grow, manufacturers are constantly working to improve their products and meet the needs of their customers.One such manufacturer is {}, a leading provider of thermal laminating machines. With a strong focus on quality and innovation, {} has established itself as a trusted name in the industry. The company offers a wide range of thermal laminating machines, catering to the needs of businesses of all sizes.Founded in 2005, {} has quickly made a name for itself as a reliable and innovative manufacturer of thermal laminating machines. The company's commitment to quality and customer satisfaction has helped it build a strong reputation in the industry. With an emphasis on research and development, {} has been able to consistently improve its products and stay ahead of the competition.One of the key factors that sets {} apart from other thermal laminating machine manufacturers is its dedication to innovation. The company invests heavily in research and development, constantly looking for new ways to improve its products and meet the evolving needs of its customers. By listening to feedback from customers and staying abreast of the latest technological advances, {} has been able to develop cutting-edge thermal laminating machines that deliver superior performance and reliability.In addition to its focus on innovation, {} is also committed to quality. The company maintains strict quality control measures throughout the manufacturing process, ensuring that each thermal laminating machine that bears the {} name meets the highest standards of excellence. This commitment to quality has earned {} the trust and loyalty of its customers, who rely on its products to protect and enhance their important documents and materials.Furthermore, {} offers a wide range of thermal laminating machines to suit the diverse needs of its customers. From compact and affordable machines for small businesses to high-capacity, high-speed machines for large-scale operations, {} has a solution for every need. The company's dedication to meeting the needs of its customers has made it a preferred choice for businesses and organizations in a variety of industries.Another key strength of {} is its commitment to customer service. The company understands that purchasing a thermal laminating machine is an investment, and it strives to provide the highest level of support to its customers. Whether it's helping customers choose the right machine for their needs, providing troubleshooting assistance, or offering maintenance and repair services, {} is dedicated to ensuring the satisfaction of its customers.As the demand for thermal laminating machines continues to grow, {} remains at the forefront of the industry. With its focus on innovation, quality, and customer service, the company has established itself as a trusted provider of thermal laminating machines for businesses and organizations around the world. Looking ahead, {} is poised to continue its legacy of excellence, providing cutting-edge solutions to meet the evolving needs of its customers.In conclusion, thermal laminating machines play a crucial role in helping businesses and organizations protect and enhance their important documents and materials. With its strong focus on innovation, quality, and customer service, {} has emerged as a leading provider of thermal laminating machines. By continuing to listen to its customers and invest in research and development, {} is well-positioned to meet the growing demand for these essential machines.